WhatsApp)

WhatsApp)

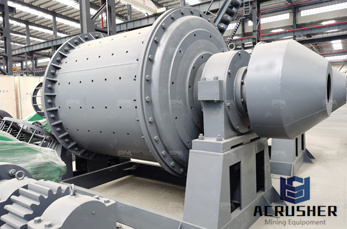

Ball Mill is key equipment of regrinding material after it improve the stability and efficiency of the ball mill, we should load and add ball reasona

Ball Mills are used for the particle size reduction of a wide variety of materials. In a range of sizes and often used in high volume applications.

ball mill for gold hard mineral mineral,mineral ball mill machine manufacturer in india ball mill for sale,mineral ball mill plant used dubai,quartz ball mill machine ...

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills ... and efficiency with increasing size. The ABBE Slice Mill is the same as the product ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

Increasing Capacity of Existing Line Grinding in a mill to the point where recycle flows, ball size distribution, and classifier tuning .... rate of the original ball ...

Ball Mill Balls on Manufacturer of balls includes ball mill balls. Specifications of ball mills include 12 in. x 12 in. cast iron drum size, 285 ball ...

Hot Products Used for standard ball mill sizes ... Ball Mill Ball Size | Crusher Mills, Cone Crusher, Jaw Crushers. ball mill size and motor power requirements ...

Savona Equipment is a new and used ball mill supplier worldwide. Savona Equipment offers new and used Ball mills for sale in the USA, Canada, Mexico and South America.

The optimal ball diameter in a mill. grinding quartz and copper ore in a laboratory ball mill, there has been defined a general form of the equation for determining ...

Ball End Mill Sizes, Wholesale Various High Quality Ball End Mill Sizes Products from Global Ball End Mill Sizes Suppliers and Ball End Mill Sizes Factory,Importer ...

Understanding Ball Mill Sizing. L. G. Austin. Ind. Eng. Chem. Process Des. Dev., 1973, 12 (2), ... Click to increase image size View: PDF. This user does not ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the .

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

Union Process can help you identify the right laboratory ball mill for your application. Contact us now to put our expertise to work for you

Video embedded· Fritsch Planetary Ball Mills are perfectly designed for a variety of lab needs. Ideal for wet and dry combination of hard, .

To match a ball mill size and its motor size, some math is required. The power requirement calculated above is the motor power that must be applied at the mill drive ...

Find great deals on eBay for Ball Mill in Metalworking End Mills. Shop with confidence.

MACSALAB Rod / Ball Mill Vessels are available in Grade 304 ... The Ball/Rod mills are meant for producing fine particle size reduction through attrition and ...

A ball mill is a type of grinder used to ... The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill.

Ball charges: This calculator ... Ball top size ... This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ...

WhatsApp)

WhatsApp)