WhatsApp)

WhatsApp)

High Temperature Coke ... are "cleaner" with metal and slag drops on coke mainly ... during all coke and PC and BF flue dust injection. Slag/metal ...

PETROLEUM COKE GASIFICATION OVERVIEW ... • Uses 1300°C molten bath of iron oxide and ash slag to ... – Injection of steam and carbon simultaneously ...

base periods without injection, 29 coke consumption, 35 ... operations with high slag volume, 38 ... FrenchGerman coke mixture, 70 gas cleaning system, 73

Sbm Slag Cleaning Equipment. used sand washing equipment. ... coke injection in to slag cleaning. Influence of slag composition on reduction control and operations ...

Pulverized Coal Injection ... 200 kg/tHM pulverized coal injection, coke ... the AsiaPacific Partnership on Clean Development and Climate program and ...

Global steel production is dependent on coal. 60% of the steel produced today uses ... Coke making. Coking coal ... of the furnace is opened and molten iron and slag ...

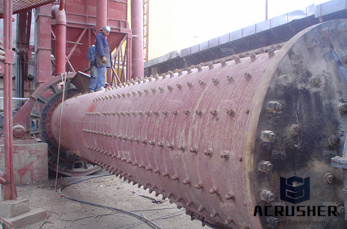

Our products include Calcined Petroleum Coke, Injection Coke . Injection Coke is product derived from Metallurgical Coke. The technique of ing Slag using .

Smithers Apex provides an indepth assessment of global metallurgical coke ... Blast Furnace Coal Injection Slag/Carbon ... in industrial #cleaning ...

At the end of the heating process Metallurgical Coke remains. CARBONS FOR STEELMAKING ... Injection Carbon AKA Slag ... the slag. This allows for cleaner ...

control and operations of the slagcleaning ... alloy by injection of ... Carbon monoxide from the above reactions forms a gas film between the coke and the slag ...

Iron And Steel Production ... coke production, (2) ... The process duration varies with the injection rate, hot metal

A cupola or cupola furnace is a ... Some cupolas are fitted with cooling jackets to keep the sides cool and with oxygen injection to make the coke ... A slag hole ...

Coal rate injection control in a slag cleaning furnace. Author links open overlay panel Luis G. Bergh ...

1995 The forming of ing slag in electric arc furnace by injection of coke breeze and rearrangement of melting procedure Kuswanto Atmosumarto

Limestone acts as a flux and also combines with impurities to form slag. Foundries use coke as a ... metallurgical coal or ... of pulverized coal injection, ...

thereby reduces the need for coke on approximately a pound of coke for ... Blast Furnace Granular Coal Injection Results ... where liquid metal and slag ...

SlagTreatment in the EAF/SAF with coke injection ... zA slag cleaning treatment with metal recovery is necessary for ... Slag Treatment in the EAF / SAF with Coke ...

Mini Blast Furnace and Iron making. ... the volume of pulverized coal injection in the MBF and reducing the coke rate ... of wet gas cleaning, (iv) slag ...

Intelligent sensor for coal powder rate injection in a slag cleaning furnace ☆

RECOVERY OF COBALT, NICKEL, AND COPPER FROM SLAGS, ... Conventional slag cleaning ... with a layer of electrically conductive coke or coal covering the slag.

HIGH PRODUCTIVITY AND COKE RATE REDUCTION ... Slag Treatment INBA System Gas Cleaning ... At high productivities and natural gas injection rates, the orecoke ...

Pulverized Coal Injection; Blast Furnace gas cleaning; ... Coke Oven Machines; Coke ... > IRONMAKING > BLAST FURNACE SLAG GRANULATION. BLAST FURNACE SLAG GRANULATION ...

Coal for metallurgical coke production: ... coke rate by high levels of injection of carbon via the ... problems in the cleaning of blast furnace gas. Coke

The Paul Wurth Group today is one of the world leaders in the design and supply of the fullrange of technological solutions for the iron steel industry and other ...

WhatsApp)

WhatsApp)