WhatsApp)

WhatsApp)

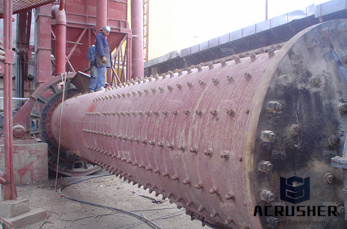

Attrition between grinding balls and ore particles causes grinding of finer particles. SAG mills are characterized by their large ... Like ball mills, grinding ...

A ball mill is a type of grinder used to grind ... Ball mills rotate around a ... Highquality ball mills are potentially expensive and can grind mixture particles ...

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as ...

Mill (grinding) – Wikipedia, the free encyclopedia. These can be related to the Hukki relationship between particle size and the energy required to break the particles.

Grinding in Ball Mills: Modeling and Process Control ... Ball mills, grinding circuit, ... Particles in the feed repetitively reduce their size due to the

How are nanoparticles generated? The "BottomUp" technique synthesizes particles from molecules or atoms. The "TopDown" technique involves reducing the size ...

How are the number of balls in ball mill grinding for grinding fly ash particles selected?

Ball mill is one of the high fine grinding machines widely ... What is a ball mill? What are its uses and advantages? ... material of feed particles small mill, ...

Ball mill ½ and larger ... Keep in mind that no single mill will grind large particles to a very fine size efficiently by repeating or prolonging the process in the ...

Why I cannot get Alumina particle in nanosize scale using ball ... ....Using planetary ball mill, the way that I use to grind them into ... energy to fuse particles ...

Small scale operations most commonly employ ball mills for grinding glaz, ... of gases around larger particles); ball, native and slip clays are an example ...

A ball mill is a type of grinder used to grind and blend materials for use in ... the grinding media particles should be substantially larger than the largest ...

normal particle size distribution of a ball mill . particle size for ball mill grind ... Grinding Mill . the production of fine particles and the width of the ...

ATTRITORS AND BALL MILLS ... Ball mills can blend and grind at the same time, ... since gravity causes the particles to fall out of the grinding zone ...

BALL Uploaded by anon ... potentially expensive and can grind mixture particles to as small as 5 ... mills are used extensively in the ...

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Effect of grinding media on the surface property and flotation behavior ... grinding media. The ball mill ... and flotation behavior of scheelite particles ...

A ball mill is an efficient tool for grinding/milling grinder many materials into fine powder / small particles / super thin / ultra fine particles. The Ball type ...

This review looks at the basic concepts of grinding mills, ... the particles go along the mill shell and then ... a ball mill in a grinding circuit ...

How Recording Tape Was Made, Circa 1955 – THE HISTORY OF . Grinding iron oxide in a ball mill. form of very fine, elongated particles was first put in ball mills ...

Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy ...

This work investigates the grinding process in tumbling ball mills using a discrete element method (DEM) based model. Binary particles are used to represent grinding ...

INTRODUCTION: Ball mill grinding is one of mechanical grinding (reduction particles to small sizes) method of ceramics. Basically ball mill is a cylindrical device ...

A cement mill (or finish mill in ... The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ...

WhatsApp)

WhatsApp)